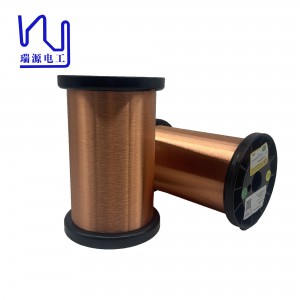

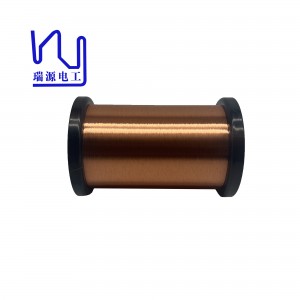

Terata e kobehileng ea koporo ea 2UEW155 0.075mm bakeng sa lisebelisoa tse nyane

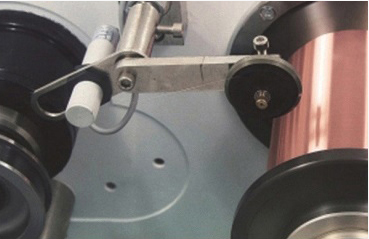

Terata ena e arotsoe ka sehlopha sa terata ea makenete e ka kopanngoang, ho bolelang hore e ka kopanngoa habonolo le likarolo tse ling, e leng se etsang hore e be thepa ea bohlokoa tlhahisong ea lisebelisoa tsa elektroniki le tsa bongaka.

Lefapheng la di-microelectronic, terata ya koporo e nang le enamel e bapala karolo ya bohlokwa tlhahisong ya dikarolo tse rarahaneng tsa elektroniki tse nepahetseng. Bophara ba yona bo bobebe haholo bo e etsa hore e lokele di-coil tse kobehang le di-transformer disebedisweng tse nyane tse kang di-sensor, di-actuator le di-micromotor. Bokgoni ba terata ya koporo e nang le enamel ho mamella dithempereichara tse phahameng bo e etsa hore e be ntle bakeng sa tshebediso di-microelectronic, ho netefatsa nako e telele le bokgoni ba disebediswa tse e sebedisang.

Terata ea koporo e nang le enamel e sebelisoa haholo lefapheng la lisebelisoa tsa bongaka. Tekanyo e nyane ea terata le thermoelasticity ea eona li e etsa karolo ea bohlokoa tlhahisong ea li-sensor tsa bongaka, li-pacemaker le lisebelisoa tsa ho nka litšoantšo. Ho tsamaisa ha eona motlakase ho phahameng ho bohlokoa bakeng sa phetiso e nepahetseng ea lets'oao tlhokomelong ea bongaka le lisebelisoa tsa tlhahlobo, e leng se tlatsetsang ho nepahaleng le ho tšepahala ha lisebelisoa tsena tsa bohlokoa.

Ho phaella moo, tlhaho ya terata ya koporo e nang le enamel e kgonang ho qhibidihiswa e dumella ho kopanngwa ho se nang moedi disebedisweng tse rarahaneng tsa bongaka, ho netefatsa kgokelo e matla le tshebetso e ntle ka ho fetisisa. Bohlokoa ba terata ya koporo e nang le enamel diindastering tsa di-microelectronic le disebediswa tsa bongaka bo ke ke ba feteletswa. Motswako wa yona o ikgethang wa bophara bo bobebe haholo, ho hanyetsa mocheso o phahameng le thepa e ka tjheselletswang e etsa hore e be karolo ya ntshetsopele ya mahlale a sejoale-joale dibakeng tsena.

Ha tlhoko ea lisebelisoa tsa elektroniki tse sebetsang hantle le tsa bongaka e ntse e eketseha, terata ea koporo e nang le enamel ntle ho pelaelo e tla lula e le sesebelisoa sa bohlokoa sa boqapi, e bapala karolo ea bohlokoa ho khanneng tsoelo-pele ea theknoloji le ho ntlafatsa tlhokomelo ea bophelo lefatšeng ka bophara.

·IEC 60317-23

·NEMA MW 77-C

·e etselitsoeng ho latela litlhoko tsa bareki.

| Lintho tsa Teko

| Litlhoko

| Lintlha tsa Teko | ||

| 1stMohlala | 2ndMohlala | 3rdMohlala | ||

| Ponahalo | Boreleli le ho Hloekisa | OK | OK | OK |

| Bophara ba mokhanni | 0.075mm ±0.002mm | 0.075 | 0.075 | 0.075 |

| Botenya ba ho kenya mocheso | ≥ 0.008 mm | 0.010 | 0.010 | 0.010 |

| Bophara ba Kakaretso | ≤ 0.089 mm | 0.085 | 0.085 | .085 |

| Khanyetso ea DC | ≤ 4.119Ω/m | 3.891 | 3.891 | 3.892 |

| Ho lelefatsa | ≥ 15% | 22.1 | 20.9 | 21.6 |

| Phallo ea Motlakase | ≥550 V | 1868 | 2051 | 1946 |

| Lesoba la Pin | ≤ liphoso tse 5/5m | 0 | 0 | 0 |

| Ho khomarela | Ha ho mapetso a bonahalang | OK | OK | OK |

| Seha ka hare | 230℃ 2min Ha ho na karohano | OK | OK | OK |

| Tšusumetso ea Mocheso | 200±5℃/30min Ha ho mapetso | OK | OK | OK |

| Ho khoneha ho rekisetsoa | 390± 5℃ 2 Sec Ha ho na slag | OK | OK | OK |

Koili ea likoloi

kutlo

transformer e khethehileng

enjene e nyane e khethehileng

inductor

Relay

E shebane le Bareki, Boqapi bo tlisa Boleng bo Eketsehileng

RUIYUAN ke mofani oa litharollo, e leng se re hlokang hore re be litsebi haholoanyane mabapi le lithapo, thepa ea ho futhumatsa le lits'ebetso tsa hau.

Ruiyuan e na le lefa la boqapi, hammoho le tsoelo-pele ea terata ea koporo e nang le enamel, k'hamphani ea rona e holile ka boitlamo bo sa thekeseleng ba botšepehi, tšebeletso le karabelo ho bareki ba rona.

Re labalabela ho tswela pele ho hola motheong wa boleng, boqapi le tshebeletso.

Matsatsi a 7-10 Nako e tloaelehileng ea ho tlisa.

Bareki ba 90% ba Europe le Amerika Leboea. Joalo ka PTR, ELSIT, STS jj.

Sekhahla sa theko hape sa 95%

Sekhahla sa khotsofalo sa 99.3%. Mofani oa sehlopha sa A o netefalitsoe ke moreki oa Jeremane.