Terata ea Koporo e nang le Enameled ea 0.05mm 2UEW/3UEW155/180 bakeng sa Khoele ea ho Tlotsa

Molao-motheo o sebetsang oa coil ea ho hotetsa koloi ke ho fetola motlakase o tlase oa matla a DC ho ba motlakase o phahameng oa DC ka ho fetola le ho lokisa motlakase o habeli o fetang ka har'a coil ea ho hotetsa khafetsa. Motlakase o phahameng o hlahisoa karolong ea bobeli ea coil ea ho hotetsa (Ka kakaretso hoo e ka bang 20KV) ebe o khanna polaka ea spark ea coil ea ho hotetsa ho ntša motlakase bakeng sa ho hotetsa. Ho thata ho laola litšobotsi tse ling tsa terata e tloaelehileng ea enamel bakeng sa likhoele tsa ho hotetsa koloi kaha terata e robehileng hangata e etsahala nakong ea ts'ebetso. Ha re nahana ka litlhoko tse ikhethang tsa likhoele tsa ho hotetsa, k'hamphani ea rona e rala terata e ikhethang ea enamel bakeng sa likhoele tsa ho hotetsa likoloi tse nang le ponahalo e ntle, bokhoni bo botle ba ho hotetsa, khanyetso e phahameng ea ho nolofatsa le botsitso nakong ea tlhahiso. Re sebelisa terata ea koporo e huloang e koahetsoeng qalong ka ho soldering ea motheo ea coat mochesong o tlase. Ebe terata e boetse e koahetsoe ka enamel e thibelang ho nolofatsa. Likarolo tsa terata ena ke polyurethane e nang le khanyetso e phahameng ea mocheso.

E 'ngoe ea litšobotsi tsa terata e nang le enamel (G2 H0.03-0.10) bakeng sa karolo ea bobeli ea coil ea ho tjhesa koloi ke hore bophara ba eona bo tšesaane haholo. E tšesaane haholo ke hoo e ka bang karolo ea boraro feela ea moriri oa motho. Ho feta moo, kaha ke terata e nang le enamel e teteaneng ea polyurethane ea sehlopha sa mocheso sa 180C, e na le litlhoko tse phahameng ts'ebetsong ea tlhahiso. Khamphani ea rona e na le boiphihlelo bo bongata le theknoloji e tsoetseng pele le e tsoetseng pele moralong oa terata e nang le enamel bakeng sa coil ea ho tjhesa koloi. Ts'ebetso ea tlhahiso e tsitsitse.

1. Ntlafatso ea khanyetso ea ho nolofatsa e le hore e se ke ea robeha nakong ea ho nolofatsa tlas'a boemo ba 260℃ * 2min.

2. tshebetso e betere ya ho kopanya, bokaholimo ba ho kopanya bo boreleli ebile bo hlwekile ntle le slag ya ho kopanya tlasa boemo ba 390℃ * 2S.

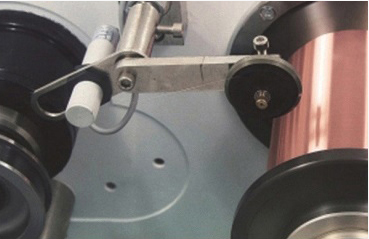

Sekhahla sa ho robeha ha terata ts'ebetsong ea tlhahiso se fokotsehile ho tloha ho feta 20% ho ea ho ka tlase ho 1%, e le hore bokaholimo bo be bo boreleli le hore motlakase o tsitse.

1. Re amohela sesebelisoa sa ho thibela ho kopana: enamel e nang le thepa ea ho kopanya mocheso o tlase e sebelisoa e le seaparo sa motheo, 'me enamel e nang le khanyetso e phahameng ea ho nolofatsa e le sekoahelo sa holimo ho hlahisa terata e kopantsoeng ea enamel e nang le bokhoni bo botle ba ho kopanya le khanyetso e phahameng ea ho nolofatsa.

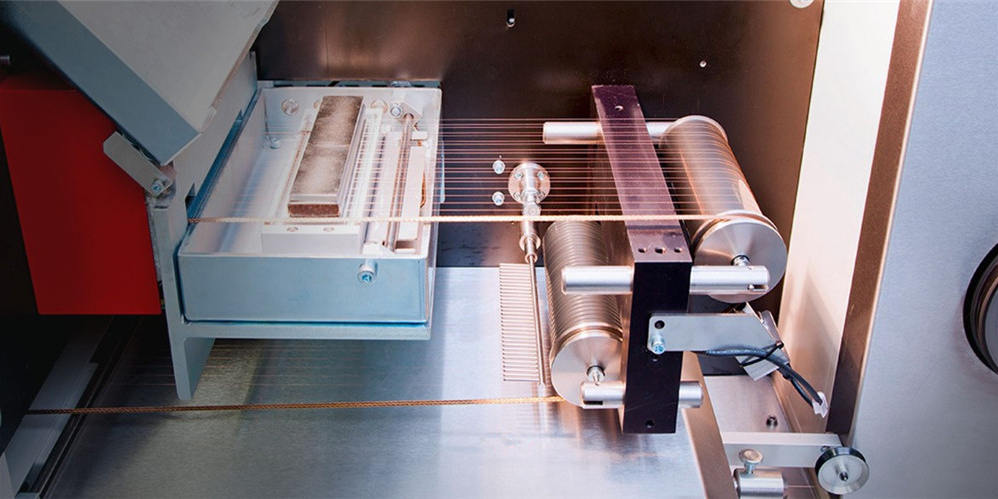

2. Ntlafatso ea theknoloji ea tlhahiso ea terata e nang le enamel: phetoho ea mahloriso a oli ea ho hula nakong ea ho hula. Sete ea hlobo bakeng sa taolo ea tlhahiso e thusa ho boreletsa bokaholimo ba terata ea koporo. Ho kenya sesebelisoa sa ho lokisa viscosity ka boiketsetso le sesebelisoa sa taolo ea khatello ea othomathiki ts'ebetsong ea enamel ho fokotsa sekhahla sa ho robeha ha terata.

| Bophara | Mamello | Terata ea koporo e nang le enamel (bophara bohle) | |||||

| (mm) | (mm) | Sehlopha sa 1 | Sehlopha sa 2 | Sehlopha sa 3 | |||

| Bonyane (mm) | Boholo (mm) | Bonyane (mm) | Boholo (mm) | Bonyane (mm) | Boholo (mm) | ||

| 0.030 | * | 0.033 | 0.037 | 0.038 | 0.041 | 0.042 | 0.044 |

| 0.032 | * | 0.035 | 0.039 | 0.04 | 0.043 | 0.044 | 0.047 |

| 0.034 | * | 0.037 | 0.041 | 0.042 | 0.046 | 0.047 | 0.05 |

| 0.036 | * | 0.04 | 0.044 | 0.045 | 0.049 | 0.05 | 0.053 |

| 0.038 | * | 0.042 | 0.046 | 0.047 | 0.051 | 0.052 | 0.055 |

| 0.040 | * | 0.044 | 0.049 | 0.05 | 0.054 | 0.055 | 0.058 |

| 0.043 | * | 0.047 | 0.052 | 0.053 | 0.058 | 0.059 | 0.063 |

| 0.045 | * | 0.05 | 0.055 | 0.056 | 0.061 | 0.062 | 0.066 |

| 0.048 | * | 0.053 | 0.059 | 0.06 | 0.064 | 0.065 | 0.069 |

| 0.050 | * | 0.055 | 0.06 | 0.061 | 0.066 | 0.067 | 0.072 |

| 0.053 | * | 0.058 | 0.064 | 0.065 | 0.07 | 0.071 | 0.076 |

| 0.056 | * | 0.062 | 0.067 | 0.068 | 0.074 | 0.075 | 0.079 |

| 0.060 | * | 0.066 | 0.072 | 0.073 | 0.079 | 0.08 | 0.085 |

| 0.063 | * | 0.069 | 0.076 | 0.077 | 0.083 | 0.084 | 0.088 |

| 0.067 | * | 0.074 | 0.08 | 0.081 | 0.088 | 0.089 | 0.091 |

| 0.070 | * | 0.077 | 0.083 | 0.084 | 0.09 | 0.091 | 0.096 |

| 0.071 | ± 0.003 | 0.078 | 0.084 | 0.085 | 0.091 | 0.092 | 0.096 |

| 0.075 | ± 0.003 | 0.082 | 0.089 | 0.09 | 0.095 | 0.096 | 0.102 |

| 0.080 | ± 0.003 | 0.087 | 0.094 | 0.095 | 0.101 | 0.102 | 0.108 |

| 0.085 | ± 0.003 | 0.093 | 0.1 | 0.101 | 0.107 | 0.108 | 0.114 |

| 0.090 | ± 0.003 | 0.098 | 0.105 | 0.106 | 0.113 | 0.114 | 0.12 |

| 0.095 | ± 0.003 | 0.103 | 0.111 | 0.112 | 0.119 | 0.12 | 0.126 |

| 0.100 | ± 0.003 | 0.108 | 0.117 | 0.118 | 0.125 | 0.126 | 0.132 |

| 0.106 | ± 0.003 | 0.115 | 0.123 | 0.124 | 0.132 | 0.133 | 0.14 |

| 0.110 | ± 0.003 | 0.119 | 0.128 | 0.129 | 0.137 | 0.138 | 0.145 |

| 0.112 | ± 0.003 | 0.121 | 0.13 | 0.131 | 0.139 | 0.14 | 0.147 |

| 0.118 | ± 0.003 | 0.128 | 0.136 | 0.137 | 0.145 | 0.146 | 0.154 |

| 0.120 | ± 0.003 | 0.13 | 0.138 | 0.139 | 0.148 | 0.149 | 0.157 |

| 0.125 | ± 0.003 | 0.135 | 0.144 | 0.145 | 0.154 | 0.155 | 0.163 |

| 0.130 | ± 0.003 | 0.141 | 0.15 | 0.151 | 0.16 | 0.161 | 0.169 |

| 0.132 | ± 0.003 | 0.143 | 0.152 | 0.153 | 0.162 | 0.163 | 0.171 |

| 0.140 | ± 0.003 | 0.151 | 0.16 | 0.161 | 0.171 | 0.172 | 0.181 |

| 0.150 | ± 0.003 | 0.162 | 0.171 | 0.172 | 0.182 | 0.183 | 0.193 |

| 0.160 | ± 0.003 | 0.172 | 0.182 | 0.183 | 0.194 | 0.195 | 0.205 |

| 0.170 | ± 0.003 | 0.183 | 0.194 | 0.195 | 0.205 | 0.206 | 0.217 |

| 0.180 | ± 0.003 | 0.193 | 0.204 | 0.205 | 0.217 | 0.218 | 0.229 |

| 0.190 | ± 0.003 | 0.204 | 0.216 | 0.217 | 0.228 | 0.229 | 0.24 |

| 0.200 | ± 0.003 | 0.214 | 0.226 | 0.227 | 0.239 | 0.24 | 0.252 |

| Bophara | Mamello | Khanyetso ho 20 °C | ||

| mm | mm | Lebitso(ohm/m) | Bonyane (ohm/m) | Boholo (ohm/m) |

| 0.030 | * | 24.18 | 21.76 | 26.6 |

| 0.032 | * | 21.25 | 19.13 | 23.38 |

| 0.034 | * | 18.83 | 17.13 | 20.52 |

| 0.036 | * | 16.79 | 15.28 | 18.31 |

| 0.038 | * | 15.07 | 13.72 | 16.43 |

| 0.040 | * | 13.6 | 12.38 | 14.83 |

| 0.043 | * | 11.77 | 10.71 | 12.83 |

| 0.045 | * | 10.75 | 9.781 | 11.72 |

| 0.048 | * | 9.447 | 8.596 | 10.3 |

| 0.050 | * | 8.706 | 7.922 | 9.489 |

| 0.053 | * | 7.748 | 7.051 | 8.446 |

| 0.056 | * | 6.94 | 6.316 | 7.565 |

| 0.060 | * | 6.046 | 5.502 | 6.59 |

| 0.063 | * | 5.484 | 4.99 | 5.977 |

| 0.067 | * | 4.848 | 4.412 | 5.285 |

| 0.070 | * | 4.442 | 4.042 | 4.842 |

| 0.071 | ± 0.003 | 4.318 | 3.929 | 4.706 |

| 0.075 | ± 0.003 | 3.869 | 3.547 | 4.235 |

| 0.080 | ± 0.003 | 3.401 | 3.133 | 3.703 |

| 0.085 | ± 0.003 | 3.012 | 2.787 | 3.265 |

| 0.090 | ± 0.003 | 2.687 | 2.495 | 2.9 |

| 0.095 | ± 0.003 | 2.412 | 2.247 | 2.594 |

| 0.100 | ± 0.003 | 2.176 | 2.034 | 2.333 |

| 0.106 | ± 0.003 | 1.937 | 1.816 | 2.069 |

| 0.110 | ± 0.003 | 1.799 | 1.69 | 1.917 |

| 0.112 | ± 0.003 | 1.735 | 1.632 | 1.848 |

| 0.118 | ± 0.003 | 1.563 | 1.474 | 1.66 |

| 0.120 | ± 0.003 | 1.511 | 1.426 | 1.604 |

| 0.125 | ± 0.003 | 1.393 | 1.317 | 1.475 |

| 0.130 | ± 0.003 | 1.288 | 1.22 | 1.361 |

| 0.132 | ± 0.003 | 1.249 | 1.184 | 1.319 |

| 0.140 | ± 0.003 | 1.11 | 1.055 | 1.17 |

| 0.150 | ± 0.003 | 0.9673 | 0.9219 | 1.0159 |

| 0.160 | ± 0.003 | 0.8502 | 0.8122 | 0.8906 |

| 0.170 | ± 0.003 | 0.7531 | 0.7211 | 0.7871 |

| 0.180 | ± 0.003 | 0.6718 | 0.6444 | 0.7007 |

| 0.190 | ± 0.003 | 0.6029 | 0.5794 | 0.6278 |

| 0.200 | ± 0.003 | 0.5441 | 0.5237 | 0.5657 |

Transformer

Motlakase

Koili ea ho hotetsa

Khoele ea Lentsoe

Motlakase

Relay

E shebane le Bareki, Boqapi bo tlisa Boleng bo Eketsehileng

RUIYUAN ke mofani oa litharollo, e leng se re hlokang hore re be litsebi haholoanyane mabapi le lithapo, thepa ea ho futhumatsa le lits'ebetso tsa hau.

Ruiyuan e na le lefa la boqapi, hammoho le tsoelo-pele ea terata ea koporo e nang le enamel, k'hamphani ea rona e holile ka boitlamo bo sa thekeseleng ba botšepehi, tšebeletso le karabelo ho bareki ba rona.

Re labalabela ho tswela pele ho hola motheong wa boleng, boqapi le tshebeletso.

Matsatsi a 7-10 Nako e tloaelehileng ea ho tlisa.

Bareki ba 90% ba Europe le Amerika Leboea. Joalo ka PTR, ELSIT, STS jj.

Sekhahla sa theko hape sa 95%

Sekhahla sa khotsofalo sa 99.3%. Mofani oa sehlopha sa A o netefalitsoe ke moreki oa Jeremane.